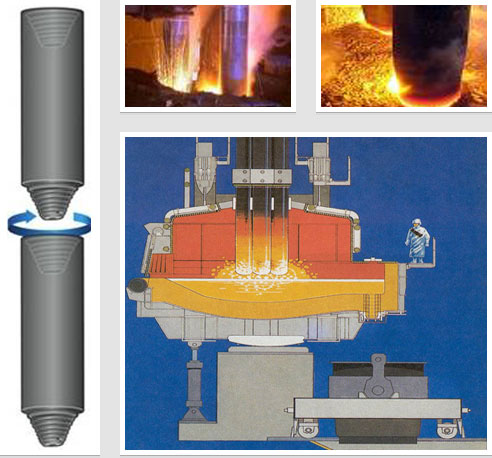

An electric arc furnace is a large pot into which scrap steel, like old cars, bicycles, and refrigerators, are dumped.

Aero Industries LLC. electrodes are part of the furnace structure. We supply and machine electrodes ranging from 75 millimeters (3 inches) in diameter, or quite large, up to 750 millimeters (30 inches) in diameter and as much as 2800 millimeters long.

The electrodes are assembled into columns, usually 3 to a column. Graphite connecting pins-tapered are threaded on each end screw two electrodes together. Each electrode column has a large steel arm which moves it up and down.

Furnaces using 3-phase AC electricity have 3 electrode columns; DC (direct current) furnaces only need one column of electrodes, but they are generally larger in diameter.

Once the furnace lid is in place, the electrodes are lowered until the tip of the electrode column almost touches the top of the scrap steel. Huge amounts of electricity flow through large water-cooled cables into the electrodes. At the bottom of the electrode column, the electricity jumps (or arcs) from the electrode tip to the nearest piece of scrap steel. The intense heat of this electric arc melts the scrap steel, hence the name of the electric arc furnace.

The tip of the electrode will reach 3,000 degrees Celsius or 5,000 degrees Fahrenheit. Electrodes are made of graphite because only graphite can withstand this incredible temperature.

Eventually all the steel is melted.